Wind Energy And Cables For The Future Of Wind Farms

Wind energy is one of the most promising renewables on the market. It is now responsible for around 10 percent of total utility electricity in the United States. As of 2022, it has experienced the largest growth among all technologies generating power. On average, wind farms are 20 to 40 percent efficient at converting wind into energy, which is high among renewables. This blog discusses the types of cables used in wind farms and what is expected of them.

The Cable Requirements For A Wind Power Application

Wind farms are exposed to rather harsh weather conditions regularly. Here are the few factors that are critical for all cables placed in wind farms:

- Resistance to oil - All cables in wind turbines should have oil resistance because they are exposed to different types of oils that could age the conductors and cause the cable jacket to harden. In case of a leakage, oil is very likely to contact the cable.

- Abrasion resistance - Blades of a wind turbine are subjected to wearing off because of their construction, so abrasion resistance is a must.

- Flexibility allows cables within the wind turbines to operate without additional stress. This is especially critical for the wires in the wind turbine's nacelle. Flexible wires also have a better reaction to vibration.

- Shielding is necessary for protection from electromagnetic interference. This is a necessity for signal and control cables.

- Resistance to sunlight - Wind turbines are exposed to the sun all year round, making this an obvious priority.

- Resistance to ozone- a crucial factor since wind turbines are located outside and are exposed to damage from the air.

- Acceptable temperature range - A typical temperature range required for a wind farm is -40°C up to 90°C. The cables must be flexible at low temperatures in colder climates.

- Flame resistance - usually confirmed by FT4 rating. This is required because of the consistent risk of fire on wind farms.

- Low Smoke Halogen-Free Properties - This is a relatively new requirement for jackets and insulation that stems from the need to protect turbines from fire in a more sophisticated way.

- Current capacity should be adequate for the expected application of the cable.

Types Of Cables Used in Wind Farms

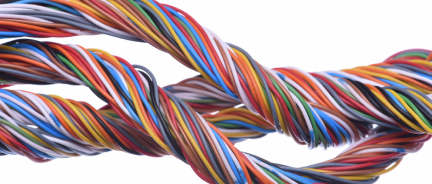

Depending on the type of applications, wind farm cables can be divided into power cables, data transmission cables, and control cables. Copper, aluminum, and fiber optic cables are used.

Power Cables: High-Voltage and Low-Voltage

Within the wind farm, power cables are used for a myriad of different applications, including submersible pumps, cooling systems, motor drives, and pitch systems. Power cables connect the nacelle of the wind engine to the base of the wind farm and connect the farm to the grid. Most importantly, they are used to operate a wind turbine. The cables discussed below are used in offshore and onshore wind farms alike.

- Two types of power cables recommended for wind farms are low-voltage and high-voltage power cables. High-voltage cables are used to carry the power, while low-voltage cables are used for less power-consuming tasks, such as lighting, heating, etc. 15KV Medium Voltage Power Cable, and 25KV/35KV Medium Voltage Power Cable are excellent multi-purpose cables for power installations in wind farms.

- DLO cables with a 2kV rating can as well be used for power applications. These robust cables with EP insulation and EPR jacket are used for power transmission between wind turbine and power source and internal turbine wiring. Other applications of DLO cables within wind turbines include transmitting the power from the generator to the nacelle, and wind turbine auxiliary powering systems. DLO cables have the right kind of durability needed for wind farms.

- PV wiring comes in handy if your farm combines wind turbines and solar panels.

- 350MCM XLP USE-2 RHH RHW-2 Copper Building Wire: XLP USE-2 RHH RHW-2 are yet another robust cable option perfect for connecting generator to the grid and other power applications.

- Aluminum TRXLP 25KV 100% Cable: This is an aluminum cable suitable medium-voltage applications within the wind farm. It can be used for interconnecting various parts of a farm, distribution of power, and underground connections.

Data Transmission and Control Cables

Just like power cables, data transmission cables bring the energy from the nacelle to the tower. Data transmission cables keep the data running in electronic devices, while control cables are designed to control the elements of wind farm mechanisms. Both of these require EMI to work in a wind farm successfully.

- Fiber Optic Cables are used for data transmission, control, and monitoring in wind farms, namely in the switchboards and in the systems of pitch control. The cables are used to carry the signal from the turbine to the data center control unit. They are a top-notch effective option that protects wind turbines from electromagnetic interference. Many sensors found on turbines are especially prone to the negative influence of electromagnetic noise.

- Copper Control and Data Cables are suitable for the transmission of temperature signals to the systems that control the temperature of the engine.

- Custom cables are miscellaneous aluminum, copper, and cables designed for various wind farm applications according to the precise demands of a particular farm. Nassau National Cable develops such cables for businesses.