Tinned Copper Wire vs. Bare Copper Wire: When Is It Best to Use Each One?

As you know, the bare copper conductor can be coated with tin for protection against corrosion. Read this blog to learn the differences between bare and tinned copper and when it is best to use the latter.

What is Bare Copper Used For?

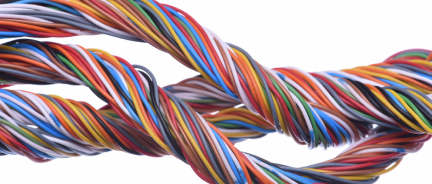

Bare copper wire refers to a single strand of copper wire that does not have an extra coating. The wire consists of 99.99 percent pure copper and can be used as a single wire in ground conductors, hook-up wiring, and jumper cables.

Bare copper is also used in multi-strand solid and stranded copper conductors. It can be hard, medium-hard, or soft annealed, depending on its properties. Bare copper is extracted from the pure copper rod and has a distinguishable orangey-red color. Bare copper has plausible corrosion resistance and high-temperature resistance properties, but they are amplified using tinned copper instead.

What Does Tinned Copper Wire or Conductor Mean?

Tinned copper is copper covered with tin (another name for solder) to preserve the qualities of the metal when exposed to harmful environments and expand its lifespan. Tin acts as an extra layer of protection against corrosion, oxidization, and the detrimental impact of high temperatures.

The tinned copper wire may consist of several tinned copper conductors or just one wire. Because the tin is a silver-colored metal, the entire conductor has a silver appearance. Tin is used to prevent oxidation because it is one of the most budget-friendly metals with the necessary properties.

Can The Copper Wire be Tinned Manually?

Not really. The copper is tinned with the help of industrial tools in a hot process called electroplating after the bare copper is extracted from the rod. You can use stripping tools to tin the ends of the copper conductor at home, but it will only serve you as much because it does not offer the entire scope protection associated with a fully tinned copper conductor.

What Is The Goal Of The Tinned Copper Conductor?

The goal of a tinned copper conductor is to provide superior protection against corrosion and oxidation in moist environments and places when the metals are contaminated, increasing the formation of rust.

Once the oxidation process starts, it is merely impossible to stop it and increase the operational time of the conductor, so preventing oxidation by using a tinned copper conductor appears to be the most plausible solution. At times, oxidation of copper starts as early as it is shelved after production, even before it is installed, and the process is almost invisible until it is too late, so prevention is the key. An oxidized copper is no longer fit to use because it loses electrical efficiency, is prone to breakage, and risks safety. An oxidized copper has a distinctive green appearance.

Tinned copper does not only protect from oxidation and corrosion. In some cases, tinned copper is also superior to bare copper when dealing with the impact of high temperatures, especially when it comes to temperatures over 100 degrees Celsius. The reason for this is that tinning helps to prevent copper heat degradation. In wet and hot environments, tinned copper can serve up to ten times longer than regular bare copper.

Are There Additional Differences in Tinned vs. Bare Copper Performance?

Since tinned copper conductor has tin in it, it is usually easier to solder than bare copper. The differences in conductivity between bare and tinned copper are not of concern.

Is Tinned Copper More Costly Than Bare Copper?

Due to the costs that stem from tinning copper, tinned copper can be up to 30 percent more pricey than its bare counterpart. However, this cost difference definitely pays off in an electrical project impacted by high temperatures, moisture, and contaminated soil.

Which Applications Are Best For Tinned Copper?

The environment is a deciding factor in the tinned vs. bare copper debate. Tinned copper is predominantly used in marine wiring that is exposed to humidity for its entire lifespan, including shipboard cables, marine oil rig cables, cables used in sewage treatment facilities, and everything else that comes in regular contact with the water. This is especially critical in seas and oceans because saltwater leads to corrosion faster than freshwater does.

Aside from this, tinned copper conductors are used in underground railway systems when exposed to moisture is guaranteed, and any electrical project is likely to be influenced by gas, oil, water, and moisture. In regions when humidity is probable for most of the year, tinned copper is used frequently in most electrical projects.

When the cable is buried underground, the decision of whether to use tinned or bare copper conductors depends on the properties of the soil. If the chemical properties of the soil are unknown, the customer decides the best course of action and chooses between tinned or bare copper conductors. If there is a risk that the chemical properties of the ground are likely to lead to corrosion, the best decision is to use tinned copper. However, it is also essential to consider cost considerations when deciding on tinned vs. bare.

Depending on the manufacturer, high-temperature wiring for stoves, furnaces, and electric heating equipment can be produced with a tinned copper conductor, though copper-plated, nickel-plated, or typical soft annealed conductors are also possible in these cases as long as they have good thermal conductivity.

In cases not affected by water, humidity, soil contamination, or high temperatures, bare copper conductors perform exceptionally well.

At Nassau National Cable, you can purchase high-quality cables with both tinned and bare copper conductors. This includes marine wire, high-temperature wire, and all of the most popular aluminum cable (XHHW, SER, SEU, RHH RHW-2 XLP USE-2, service drop, URD) and copper building wire (THWN-2, XHHW-2, XLP USE RHH RHW-2, UF-B, SEU, SER NM-B ROMEX) varieties. We also sell bare copper cables for overhead power transmission and distribution, both bare and tinned.